Kev ua cov hniav thoob zoo muaj ntau yam, txij li kev xaiv cov khoom siv mus rau cov txheej txheem tsim khoom thiab kev tswj xyuas zoo. Nov yog cov kauj ruam tseem ceeb:

1. Kev Xaiv Khoom Siv

Xaiv cov hlau sib xyaw uas tsim nyog: Cov hlau sib xyaw zoo feem ntau siv rau cov hniav thoob. Piv txwv li, cov hlau uas muaj cov manganese ntau tuaj yeem tiv taus kev hnav thiab tawv. Cov hlau manganese tuaj yeem ua haujlwm - tawv thaum muaj kev cuam tshuam, uas zoo tagnrho rau cov xwm txheej ua haujlwm hnyav ntawm cov hniav thoob.

Xav txog cov khoom siv uas kho tau los ntawm cua sov: Qee cov khoom siv tuaj yeem kho tau los ntawm cua sov kom txhim kho lawv cov khoom siv kho tshuab. Piv txwv li, cov hlau sib xyaw nrog cov ntsiab lus xws li chromium, nickel, thiab molybdenum tuaj yeem raug quenched thiab tempered kom ua tiav lub zog siab thiab tawv.

2. Kev Tsim Qauv Zoo Tshaj Plaws

Cov duab ergonomic: Tus qauv ntawm cov hniav thoob yuav tsum tau ua kom zoo rau kev khawb av zoo. Cov hniav uas tsim tau zoo tuaj yeem txo qhov kev tiv thaiv thaum khawb av, uas tsis yog tsuas yog txhim kho kev ua haujlwm zoo xwb tab sis kuj txo qhov hnav ntawm cov hniav. Piv txwv li, cov duab tapered ntawm qhov kawg tuaj yeem nkag mus rau hauv cov khoom siv tau yooj yim dua.

Kev faib tawm ntawm kev ntxhov siab: Tshuaj xyuas qhov kev faib tawm ntawm kev ntxhov siab ntawm cov hniav thoob thaum lub sijhawm ua haujlwm. Los ntawm kev siv computer-aided design (CAD) thiab finite element analysis (FEA) software, cov engineers tuaj yeem ua kom ntseeg tau tias cov hniav tuaj yeem tiv taus cov cheeb tsam siab - kev ntxhov siab yam tsis muaj kev puas tsuaj ua ntej. Kev txhawb nqa tuaj yeem ntxiv rau cov khoom tseem ceeb ntawm kev tsim qauv.

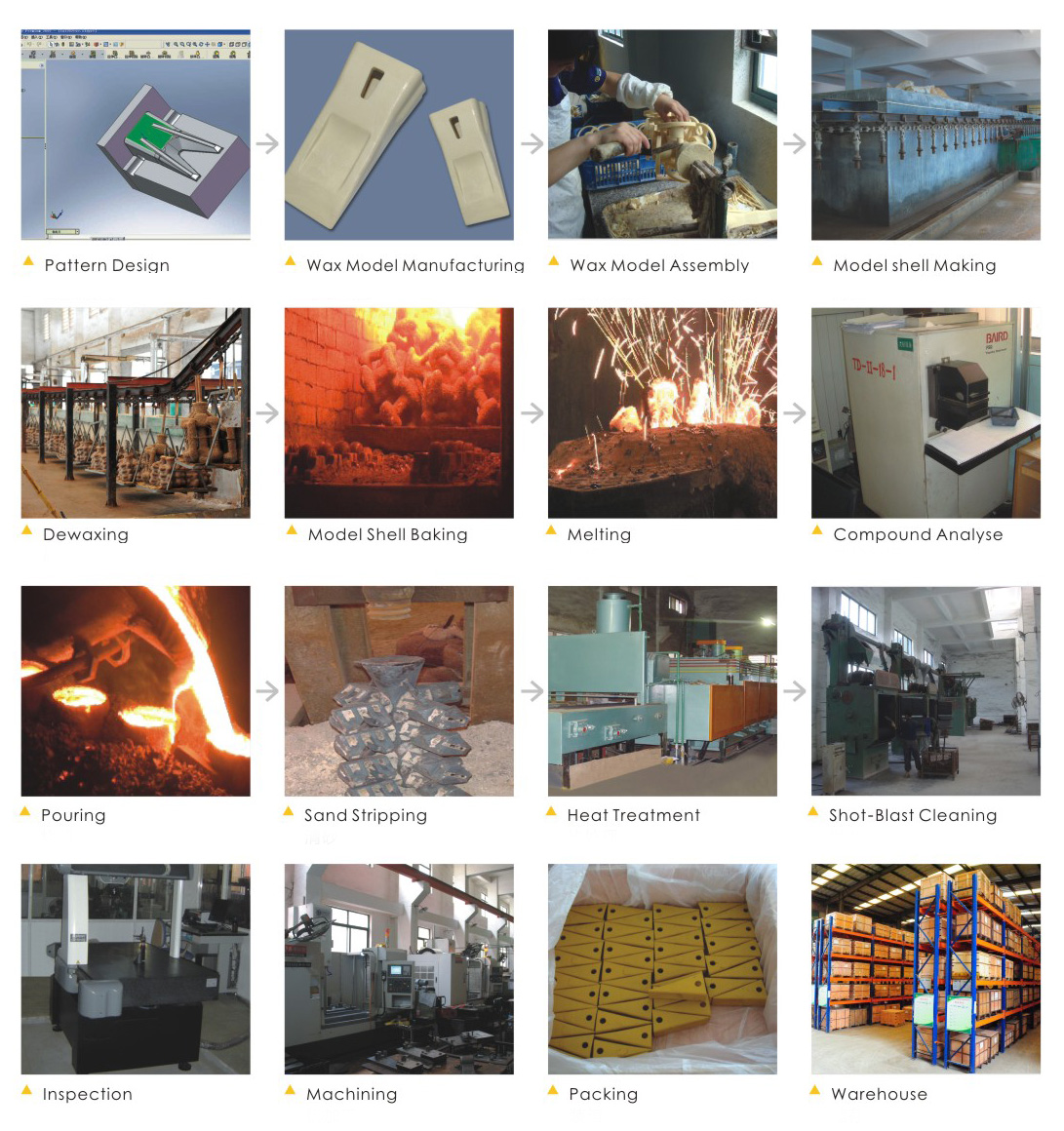

3. Txheej Txheem Tsim Khoom

Precision casting los yog forging:

Kev Txhaj Tshuaj: Kev txhaj tshuaj precision tuaj yeem tsim cov duab nyuaj nrog qhov raug siab. Piv txwv li, kev txhaj tshuaj peev txheej tuaj yeem tsim cov hniav thoob nrog cov nto du thiab cov ntsiab lus zoo. Txawm li cas los xij, nws yog ib qho tseem ceeb kom tswj cov txheej txheem casting kom tsis txhob muaj qhov tsis zoo xws li porosity thiab inclusions.

Kev Forging: Cov hniav forged feem ntau muaj cov khoom siv kho tshuab zoo dua li cov uas cam khwb cia. Kev forging tuaj yeem ua kom cov qauv ntawm cov hlau sib dhos, txhim kho nws lub zog thiab kev tawv. Nws yog ib qho txheej txheem siv zog ntau dua tab sis ua rau cov khoom zoo dua.

Kev kho cua sov: Tom qab pib ua cov txheej txheem, kev kho cua sov yog qhov tseem ceeb heev. Kev quenching thiab tempering tuaj yeem kho qhov nyuaj thiab toughness ntawm cov hniav thoob. Cov kev kho cua sov, xws li kub, lub sijhawm cua sov, thiab tus nqi txias, yuav tsum tau tswj hwm kom zoo kom ua tiav cov khoom xav tau.

Kev sim tsis ua puas tsuaj: Siv cov txheej txheem sim tsis ua puas tsuaj xws li kev sim ultrasonic, kev sim cov khoom sib nqus, lossis kev sim X-ray los nrhiav cov qhov tsis zoo sab hauv ntawm cov hniav thoob. Qhov no pab kom ntseeg tau tias cov khoom ua tau raws li cov qauv zoo ua ntej lawv xa tawm.

Kev kuaj xyuas cov khoom siv kho tshuab: Ua cov kev kuaj xws li kev kuaj qhov nyuaj, kev kuaj tensile, thiab kev kuaj kev cuam tshuam los xyuas kom meej cov khoom siv kho tshuab ntawm cov hniav thoob. Cov qauv raug coj los ntawm cov pawg ntau lawm kom ntseeg tau tias qhov zoo tag nrho yog sib xws.

5. Kev Kho Mob Nto

Txheej: Siv cov txheej uas tiv taus kev hnav rau ntawm qhov chaw ntawm cov hniav thoob tuaj yeem ua rau lawv ruaj khov dua. Piv txwv li, cov txheej ceramic tuaj yeem muab kev tiv taus kev hnav zoo heev, txo qhov kev hnav thaum lub sijhawm ua haujlwm.

Kev pleev xim los yog pleev xim: Cov kev kho mob no tuaj yeem tiv thaiv cov hniav thoob los ntawm kev xeb, tshwj xeeb tshaj yog thaum lawv siv rau hauv qhov chaw ntub dej lossis xeb. Kev pleev xim tsim ib txheej zinc rau ntawm qhov chaw, thaum pleev xim muab kev tiv thaiv tiv thaiv cov dej noo thiab tshuaj lom neeg.

Lub sijhawm tshaj tawm: Plaub Hlis-10-2025